Installation Method

This installation instruction is to be used for thin laminate flooring (8mm–12mm) with a HDF core and an integral locking system in HDF. This instruction is written by laminate flooring manufacturer as support for users, carpenters and dealers of flooring with our patented mechanical locking system.

Important Information : Please read this before installation.

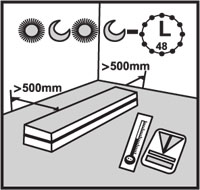

The floor panels should be transported in a lying down position. Floor panels should be stored in this position in their unopened packages in a dry storage location.

Allow the floor panels to acclimatize (in its unopened packaging) with its surrounding for 48 hours prior to installation. The room temperature must be at least 18°C (65°F) before and during installation.

Inspect the floor panels before laying. Complaints on materials that have been used will not be entertained. Unused panels from opened packages should be re-sealed in their original packing with adhesive tape.

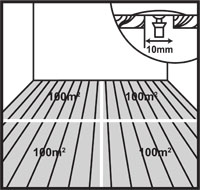

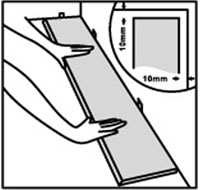

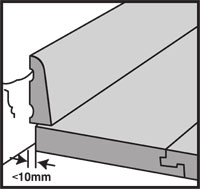

The floor panels should be laid as a floating floor system and should not be fixed, in any way, to the sub-floor or to any vertical structure. Ensure that proper gaps of at least 10mm (3/8 inches) from the walls and any vertical structures are maintained during installation. These gaps are to be concealed with suitable skirting or expansion profiles after installation.

Remove any flooring strips. Measure the room accurately, at right angle to the direction of the floorboards. The floorboards in the final row should be at least 5cm wide. If necessary, the floorboards in the first row can be cut to smaller size. Tools needed to install the flooring are a pad saw or a fine-toothed handsaw and an installation kit containing spacer blocks and a installation tool. You also need an underlayment (paper or foam) and in certain cases 0.2 (.008) mm plastic film for insulation against damp.

Suitable expansion profiles should be used at door threshold and if the length and width of the floor exceeds 12m and 8m respectively.

|

Step 1 Among the tools that you will need. |

Step 2-1  Step 2-2 |

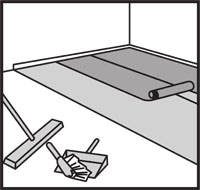

Step 2 The sub-floor surface should be dry (max 60% RH, at 18°C), reasonably flat, even (max 3mm/m) and clean before the installation is carried out. |

|

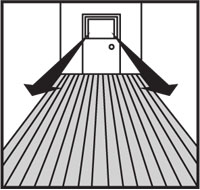

Step 3 For a better visual effect, the panels should be laid in a way that in-coming light falls along the length of the planks OR simply install them along the direction of the length of the room. |

|

Step 4 Floor areas more than 100m² (1,076.40sq.ft) with dimensions greater than 12m (39.37 feet) in either length or width, in transition between two rooms and asymmetrical floor areas requires expansion gaps in the floor installation. |

|

Step 5 After the cleaning of sub-floor, you can roll over the polyethylene sheets, which act as a moisture barrier, should be laid – with 40mm (1.58 inches) extra as skirting around the wall. Joining of the sheets should have an overlapping of at least 200mm (7.87 inches), fastened with adhesive tape. A suitable underlay should be laid on top of the polyethylene sheet, fastened with adhesive tape. |

|

Step 6 It is advised that you begin from the left-hand corner, with the tongue of the board facing the wall. Always ensure that you allow an expansion gap of at least 10mm (3/8 inches) between the panels and the wall (or any vertical structures) by using wooden spacers or cutouts from some leftover panels. If the wall is not straight, trim the panels according to the contour of the wall.; |

|

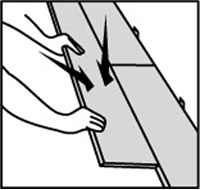

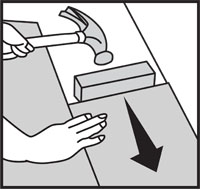

Step 7 To put the second panel into place, join the width side of the second panel with the width side of the first panel, push them together firmly and fasten the joint by pushing the panel down flat onto the sub-floor. If the joining is not tight, use a hammer and a suitable tapping block and tap gently at the other end of the second panel, if necessary. Complete the first row in the same manner. |

Step 8-1  Step 8-2  Step 8-3 |

Step 8.1, 8.2 & 8.3 At the end of the first row, mark and cut the last panel to obtain the suitable size / shape to fit the remaining space. Cut the panel with the décor side facing up if using a fine-toothed handsaw, and with the décor facing downwards if using a jigsaw. |

|

Step 9 To start the second row, use the leftover piece of the last panel from the first row. This should be longer than 300mm (11.81 inches) for a better effect. If not, saw half of a new panel to start the second row. Ensure that the end joints are spaced at least 300mm apart in consecutive rows. |

|

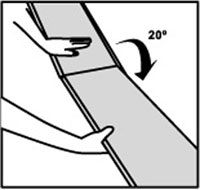

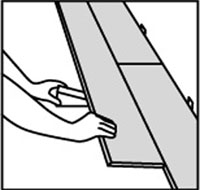

Step 10 Place the floorboard at an angle against the floorboard in the previous row, press forward and fold down at the same time. |

|

Step 11 Place the wedge underneath the floorboard as shown in the picture |

|

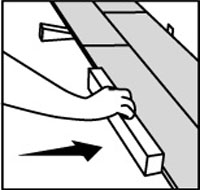

Step 12 Place the short end / width side of the floorboard at an angle against the previous installed panel and fold down. Ensure that the board is positioned on the integral locking strip of the floorboard in the previous row. |

|

Step 13 Then, using a wooden hammering block; fit the new panel into place by knocking on along the length, while pushing the panel down firm. |

|

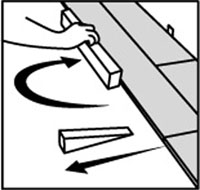

Step 14 Leave the wooden wedge from the panel. Then use the wooden block to tap gently along the length. |

|

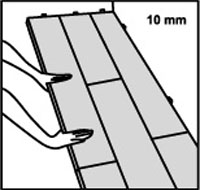

Step 15 The distance to the walls can be adjusted when three rows are completed. Place the flooring 10mm from the wall |

|

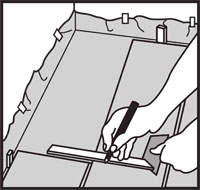

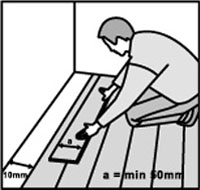

Step 16 If the wall is uneven, the floorboards must be adapted to its contours. Mark the floorboards with the contour of the wall. Do not forget to leave a 10mm to the wall. |

|

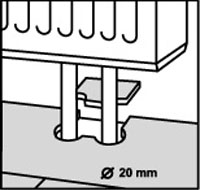

Step 17 Holes for pipe: measure the diameter of the pipe and drill a hole that is 10mm larger. Saw off a piece as shown in the figure and lay the board in place on the floor. Then lay the sawed-off piece in the place. |

|

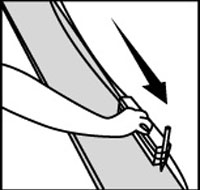

Step 18 For installation towards the doorframe, measure & cut the doorframe as floorboard height. |

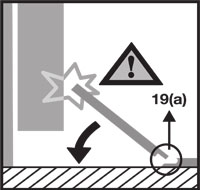

Step 19-1  Step 19-2  Step 19-3  Step 19-4 |

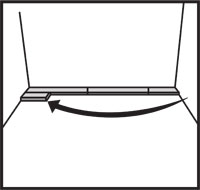

Step 19.1, 19.2, 19.3 & 19.4 Measure and cut the floorboards in the last row to size. Allow 10mm distance to the wall. For installation of last row, place the width side of panels at an angle of 20° against the others. Place the pre-installed row onto the floor and put it down when the floorboards are positioned tightly together. |

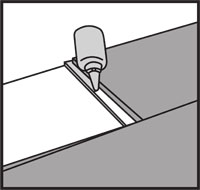

Step 20-1  Step 20-2  Step 20-3  Step 20-4  Step 20-5 |

Step 20.1, 20.2, 20.3, 20.4 & 20.5 If you are not able to angle the panels (e.g. under a doorframe, radiator or last row of installation), cut away the locking edge of lip of the bottom groove by using a wood chisel. Apply a bead of glue on the modified groove. Gently tap the floorboards together. |

|

Step 21 Finally, remove all spacers along the walls. Fix the skirting / baseboard to the wall with suitable fastening channels. Please remember that the skirting profiles should only be fixed to the walls and are not to be fastened to the laminate floor panels in any way. |

Additional points to note:

-

Sub-floors:

This laminate flooring can be installed on the following sub-floors:

Wood/timber, tiles and ceramics, marble/stone floors, linoleum/PVC and other solid/hard floor types. It is strongly advised that soft sub-floor such as carpet and similar be removed before installing laminate flooring.

The sub-floor must be even, flat, dry and variations should not exceed +/- 2mm (.08 in 6.6’). One wooden floors, the flooring is normally laid across the existing floorboard.

All type of concrete, wooden and ceramic surfaces must be completely dry:

- For wood surfaces, moisture rate corresponding to 50% RAH

- For concrete screeds CM <2.0%

- For anhydride screeds CM < 0.5%

All types of concrete and ceramic sub floors require insulation against dampness. This is also required for concrete floors with built-in moisture barrier or heating and concrete floors with resilient floor covering. Use moisture barrier film with a minimum thickness of 0.2mm (.008) and allow for at least 20cm (8”) overlapping before taping. Turn the film upwards along the walls and trim when the laying of the floor is completed.

Underlayment must be used over the entire installation when installing. Use underlayment paper or foam with a thickness of 1-3mm (0.39 – 12).

-

Floor heating:

This laminate floor can be laid over hot-water under floor heating system. However, it is possible that slight gaps might develop between the floor panels when the heating is active, or due to changes in atmospheric conditions and this does not constitute grounds for complaints.

Follow the instructions for the sub-floor heating system supplied by the manufacturer/ contractor. Also note the following: Turn the sub-floor heating off for 2-3 days so that the floor has room temperature prior to laying. The surface temperature of the floor must not exceed 28°C (82°F) and maximum output from the heating able must not exceed to 60 W/m². Make sure that the floor surface has no hot and cold areas, as this will cause tension in the floor when the heating cables are in use.

Turn on the heating system after laying is completed. We recommend following start up procedure: During the first week, the heating should be set to low or medium for 12 hours per day. During the next week, set the heating to medium output, 24 hours per day. After the initial period, the heating can be regulated in a normal way. Note that when using carpets, the surface temperature of the floor might be higher than recommended.

-

Clearance for door opening:

Always check the thickness of the floor panels with the underlay beneath to ensure that there is enough clearance for doors to open. If not, necessary modifications should be carried out to ensure that doors open easily after the flooring is installed.

-

Cleaning:

Do not pour water directly onto the floor during cleaning. The surface of laminate flooring is designed for easy maintenance, and cleaning can simply be done with a slightly damp mop or vacuuming. Laminate floor does not stain easily, and almost all stains can be removed with suitable household cleaning agents.

It is advisable to use a doormat at main entrances to protect the floor and to keep it clean.

Clean the flooring at regular intervals with vacuum cleaner or dry mop. Alternatively, use synthetic detergent and a well wrung damp cloth. Avoid using large amounts of water. Spillage must be dried up immediately. Carpets in the entrance areas will protect against sand and dirt. Felt pads should be fitted to furniture legs to avoid marking.

A room’s relative air humidity is ideally 40 – 50% at 20°C (68°F). During cold periods with increased heating, the indoor air humidity may become so low that the floor is prone to drying out. This cause a certain amount of separation so that minor gaps appear in the flooring joints. Such problems can be overcome by the use of a room humidifier.

-

Installation diagrams provided above:

Please note that these diagrams are meant as reference only. Floorboards, tools and all other items are not drawn according to actual scale.

-

Gaps

As wood is a living material (inherent hygroscopic properties), gaps can appear on joints between floorboards due to air conditioning, seasonal variation, underfloor heating (electrical system not recommended) or exposure to and subsequent drying of excessive water. This is not considered as defects.

Enquiry Form